Home .

Testing Capabilities .

Research .

Downloads .

Contacts .

Links

Attenuating Mass Concrete Effects in Drilled Shafts

FDOT Project #BD-544-39

Voided Shaft Construction Details

Task 3: Site and Construction Details

Voided Shaft Construction Time Lapse Photos

Voided Shaft Construction WebCam Archive

Voided Shaft Construction Photos

Thermocouple Data

Thermal Integrity Test Data for Tube 5 at 6AM

Thermal Integrity Test Data for Soil Tube 1/2-Diameter at 6AM

Data Logger Battery Voltage

Boring Log

Introduction

Florida’s tremendous population growth has forced roadways and the associated highway structures to be constantly upgraded to maintain a reasonable level of service. As a result, structurally sound bridges have been become functionally obsolete prior to their projected usable life span which has required their replacement. This growth coupled with more stringent design criteria to accommodate extreme event design states has led to larger and larger sub-structural bridge elements that require scrutiny with regards to mass concrete issues.

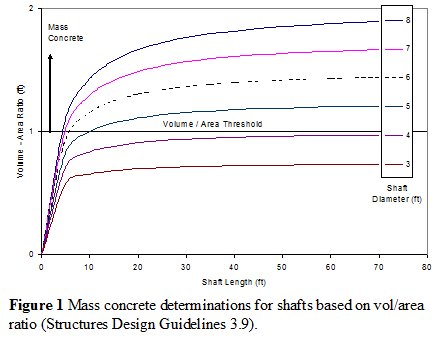

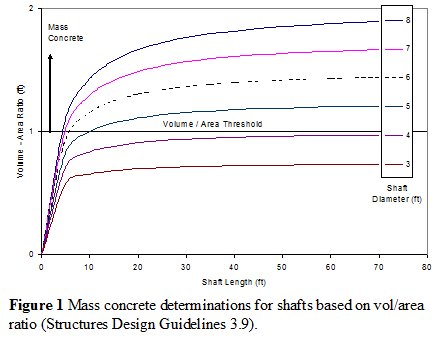

Historically, mass concrete elements were those concrete structures so massive that heat formation due to hydration reactions would induce cracking as a result of the excessive temperature differentials. These conditions were anticipated and dealt with on footings and in some cases pier columns and caps. Until very recently, drilled shafts were not thought to exhibit mass concrete effects either due to their relative small diameters (4 ft diam. typical) and/or the perception that the surrounding environment was not conducive to producing mass concrete conditions. However, the larger diameter shafts (9 ft diam.) used for the Ringling Causeway Bridge in Sarasota raised concerns that perhaps shafts had been slipping through the mass concrete specifications without review. Without quantify-able values for mass concrete effects in shafts the State assigned a somewhat arbitrary size of 6 ft diam to delineate when mass concrete specification should be imposed until more information could be obtained. The traditional volume to area ratio limit from the SDG 3.9 would have been a bit more restrictive limiting it to 4 ft diam.

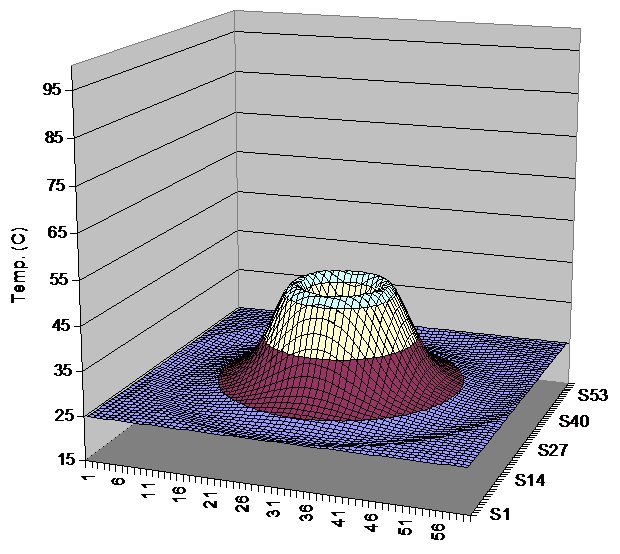

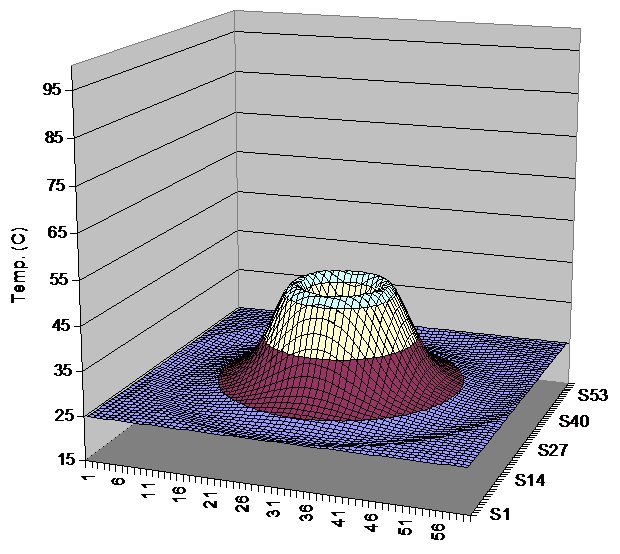

A second issue plaguing State Materials Engineers deals with delayed ettringite formation (DEF) in mass concrete of all kinds of which drilled shafts are now included. DEF arises when the peak concrete temperature exceeds values in the range of 60 deg C.

Shafts as small as 2 ft in diameter have been shown to exhibit mass concrete conditions (either differential or peak temperature limits) under certain circumstances. This somewhat startling finding has lead to an innovative construction process whereby mass concrete conditions can be averted by casting shafts with a full length centralized void (cast in place cylinder pile of sorts).

This project will apply new field temperature measurement equipment to measure the full length temperature profile of large diameter drilled shafts (both voided and unvoided) and compare those values with modeled results with a new 3-D thermal generation software. The software will ultimately be used by the State to assess the actual mass concrete potential for upcoming projects.

Objectives and Supporting Tasks

The objectives of this project are somewhat diverse but all relate to better understanding, prediction, and field measurement of mass concrete conditions and how to minimize the adverse effects.

The proposed research will undertake: (1) field temperature measurements of mass concrete structures with specific interest on drilled shafts (but not limited to) using the new thermal integrity probe, (2) numerical thermal modeling to verify the anticipated temperature response within a drilled shaft or mass concrete structure, (3) construction of a large diameter shaft with a centralize void to assess the constructability and temperature mitigation potential, and (4) development of a concrete maturation-dependent stress analysis algorithm to assess differential temperature-induced concrete cracking potential.

9ft Diameter Shaft Temp

9ft Diameter Shaft Temp

9ft Diameter Shaft with Void

9ft Diameter Shaft with Void

Contact Us

If you have questions or comments regarding Attenuating Mass Concrete, please contact Gray Mullins at gmullins@eng.usf.edu.

9ft Diameter Shaft Temp

9ft Diameter Shaft Temp

9ft Diameter Shaft with Void

9ft Diameter Shaft with Void