Home .

Testing Capabilities .

Research .

Downloads .

Contacts .

Links

Thermal Integrity Testing of Drilled Shafts

Introduction

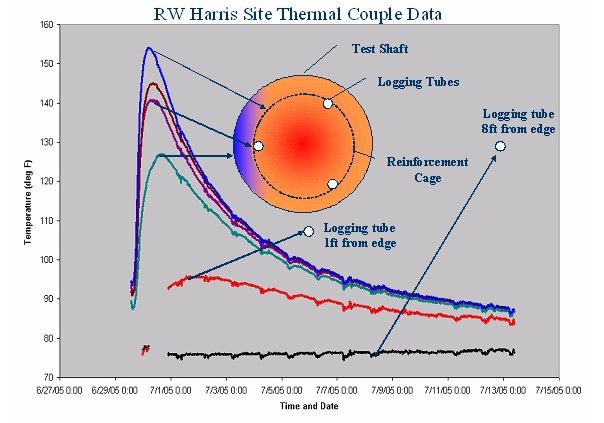

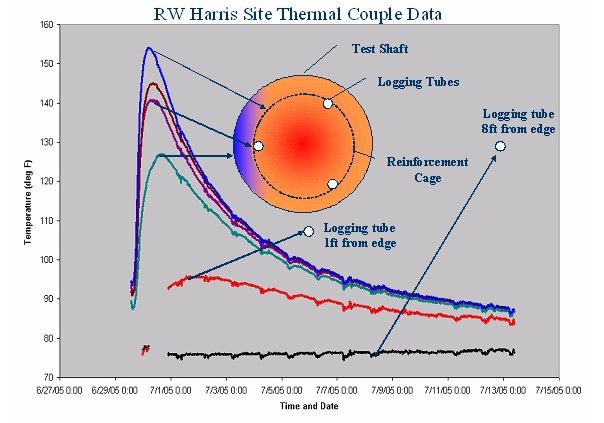

Drilled shafts are large-diameter cast-in-place concrete structures that can develop enormous axial and lateral capacity and consequently are the foundation of choice for many large bridges subject to extreme event loads such as vessel collisions. Many drilled shafts are constructed in the State of Florida using the slurry method as a means to stabilize the excavation. This means that both excavation and concreting are blind processes which increase the chance of unwittingly producing defects in the shaft. One method to assess the presence of defects makes use of the heat of hydration of curing concrete and temperature measurements within the shaft from access tubes to assess whether or not anomalies have been formed. Prior to the advent of this approach this heat was considered an undesired side effect which has been long recognized for its potentially harmful consequences. Further, thorough understanding of this phenomenon lends itself to evaluating massive concrete structures that may be seriously compromised by detrimental extremes in the internal temperature

This project investigated the merits of a new easy-to-use method of assuring shaft integrity via infrared thermal detection methods that can assess the presence or absence of intact concrete both outside and inside the shaft reinforcement cage. The system makes use of CSL tubes typically installed in production shafts (steel or PVC) and a down-hole temperature probe.

Objectives

The primary objective of this study was to assess the capability of thermal integrity testing as a viable means to provide quality assurance for drilled shafts. To this end, the project tasks were three-fold:

Review data collection and sensor systems capable of making the required measurements and develop a robust down-hole device,

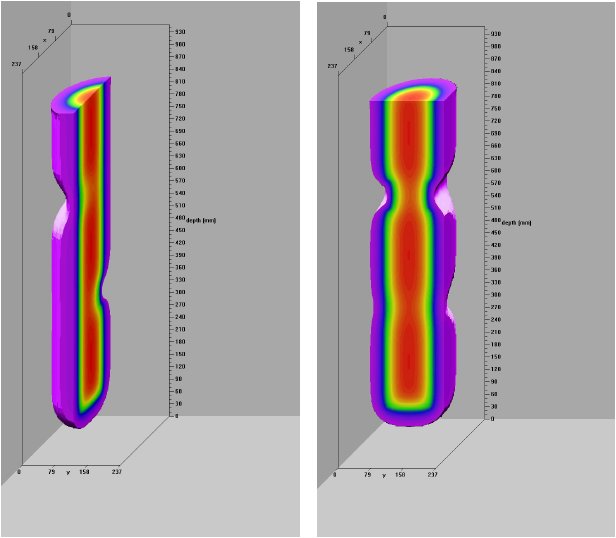

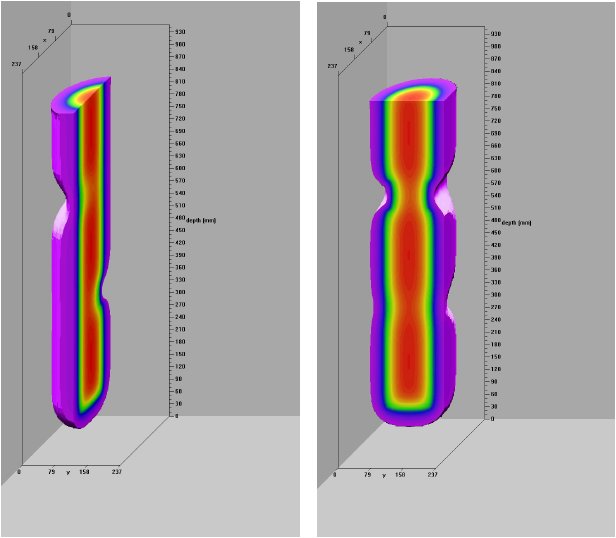

Review existing temperature prediction software that deal with concrete hydration and develop a 3-D thermal analysis package expressly for verifying thermal scans of drilled shafts, and

Collect temperature data from full-scale shaft pours, both production and experimentally based to assure equipment capabilities and provide calibration data for the 3-D thermal package.

A related topic also addressed was identifying when drilled shafts should be considered as mass concrete.

Contact Us

If you have questions or comments regarding Thermal Integrity Testing, please contact Gray Mullins at gmullins@eng.usf.edu.